Products and Technologies

AMHS is built on the basis of technical strength and trust Zunxin AMHS

Zunxin AMHS

Control systems & Solutions

Can maximize the efficiency and productivity of automation equipment.

Complete automation solutions.

Learn more about what our system offers.

Learn more about what our system offers.

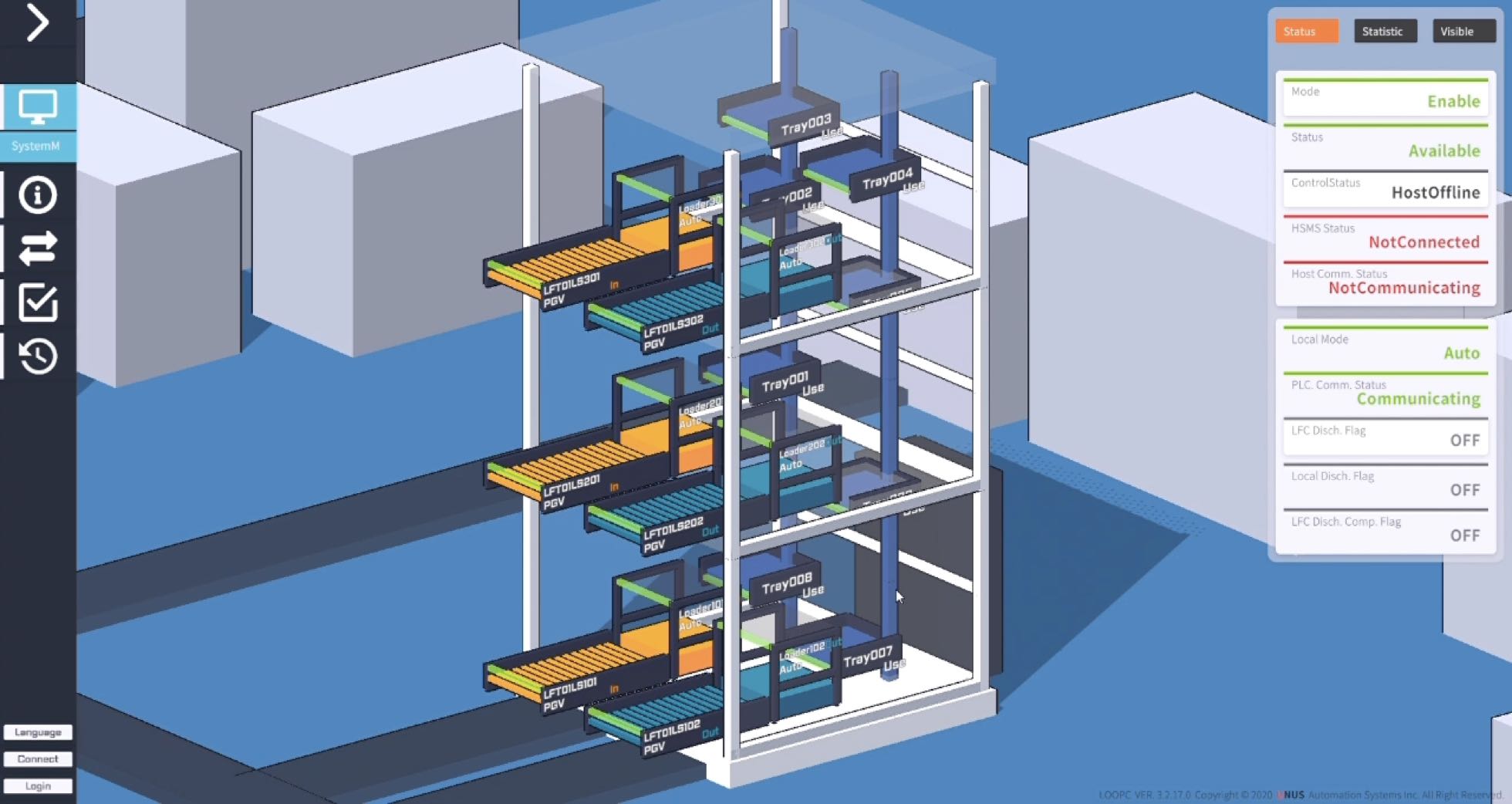

LCS

Loop Carry

Control System

Through the assembly system with various transport aircraft, the operation efficiency is greatly improved.

NTBS

NTB Control System

Through automatic control, data management, environmental control and other functions.

Efficient, stable, fast, flexible, safe and reliable to ensure the normal operation of material transmission and the stability of the production line.

Efficient, stable, fast, flexible, safe and reliable to ensure the normal operation of material transmission and the stability of the production line.

CVS

OHCV&CV Control System

Through the assembly system with various transport aircraft, the operation efficiency is greatly improved.

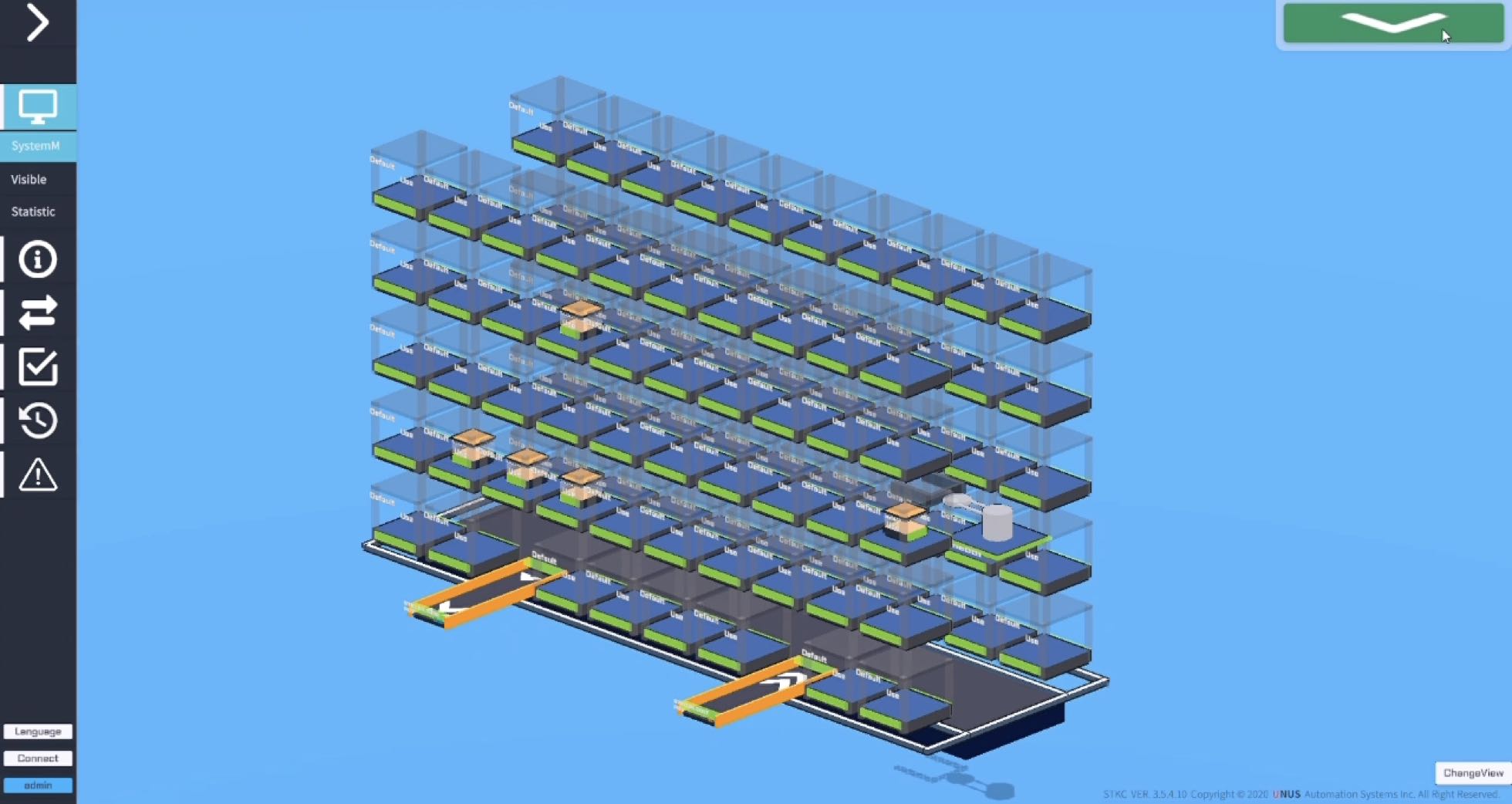

SCS

Stocker

Control System

Through SECS,TCP/IP,MQTT to connect with the upper MCS and devices STK, OHT.

Automated storage management and incoming and outgoing storage management are completed by dispatching STK. The task result is reported to the upper system in real time, and all the stored data is recorded and counted.

Automated storage management and incoming and outgoing storage management are completed by dispatching STK. The task result is reported to the upper system in real time, and all the stored data is recorded and counted.

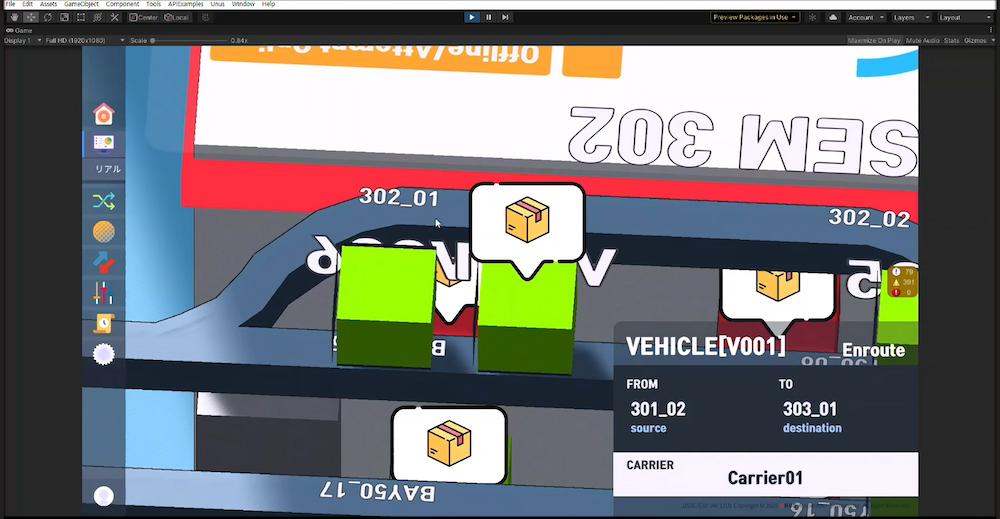

OCS

OHT Control System

By connecting with the upper system and corresponding production storage devices, the optimal path is planned to carry Foup to the Load/Unload Port among the process devices, which can effectively save and utilize space, greatly improve the carrying efficiency and save the carrying time.

Scheduling layer

Material Control System

MCS transport path planning method:

MCS system runs through internal logic and plant wide equipment

And the real-time situation of logistics delivery, comprehensive judgment,

Automation of production logistics for products manufactured in smart factories.

MCS system runs through internal logic and plant wide equipment

And the real-time situation of logistics delivery, comprehensive judgment,

Automation of production logistics for products manufactured in smart factories.

Advantage:

MCS can know the status of the moving equipment in real time, Ensure that the selected transport path can complete the transport MCS can know the status of moving tasks in real time, Select the moving path with the least amount of moving to complete the moving.

MCS can know the status of the moving equipment in real time, Ensure that the selected transport path can complete the transport MCS can know the status of moving tasks in real time, Select the moving path with the least amount of moving to complete the moving.

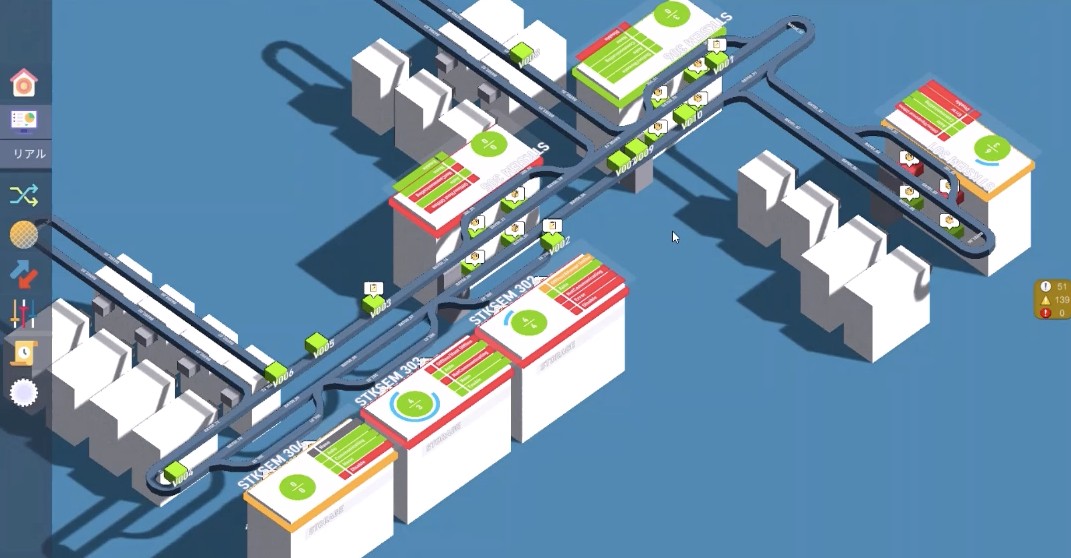

Real Time Monitor

Reporting System

Real Time Monitor

Real Time Monitor

(SCADA System for handling equipment)

Through the network, the information obtained by a series of handling equipment is concentrated in one system for supervision and analysis.

With this system, it is easy to confirm and control the status of all the machines scattered throughout the plant.

With this system, it is easy to confirm and control the status of all the machines scattered throughout the plant.

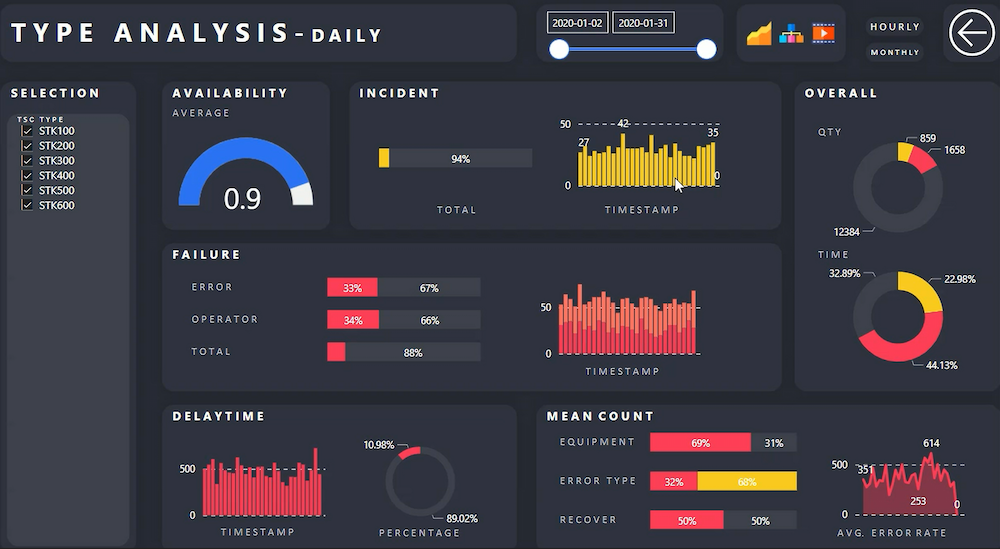

Reporting System

Reporting System

(Transporting equipment BI System)

Store all data related to transportation, shipment, and inspection, and provide Key Point Index (KPI) data related to equipment availability, reliability, and efficiency from the point of view of users, engineers, and managers.

A system that helps you make decisions while preventing errors and improving forecasting and productivity

A system that helps you make decisions while preventing errors and improving forecasting and productivity

控制层

Through the assembly system with various transport aircraft, the operation efficiency is greatly improved.

Through automatic control, data management, environmental control and other functions.

Efficient, stable, fast, flexible, safe and reliable to ensure the normal operation of material transmission and the stability of the production line.

Efficient, stable, fast, flexible, safe and reliable to ensure the normal operation of material transmission and the stability of the production line.

Through the assembly system with various transport aircraft, the operation efficiency is greatly improved.

Through SECS,TCP/IP,MQTT to connect with the upper MCS and devices STK, OHT.

Automated storage management and incoming and outgoing storage management are completed by dispatching STK. The task result is reported to the upper system in real time, and all the stored data is recorded and counted.

Automated storage management and incoming and outgoing storage management are completed by dispatching STK. The task result is reported to the upper system in real time, and all the stored data is recorded and counted.

By connecting with the upper system and corresponding production storage devices, the optimal path is planned to carry Foup to the Load/Unload Port among the process devices, which can effectively save and utilize space, greatly improve the carrying efficiency and save the carrying time.